Castheon is a part of the ADDMAN Group, which means that our customers have access to a complete range of manufacturing services, from initial design to the end of a product’s life cycle. Our customers benefit from the integration of polymer 3D printing, injection molding, and traditional manufacturing services with our cutting-edge metal additive capabilities. This allows us to offer a complete solution to our customers, making us a one-stop-shop for all their manufacturing needs. With our expertise in metal additive manufacturing and our access to a full range of manufacturing services, we can help you create the products you need, quickly and efficiently.

Your One-Stop Shop for All Your Manufacturing Needs

The Benefits of Working with Castheon and ADDMAN

At Castheon, we are proud to be part of the ADDMAN Group, which means our customers have access to polymer 3D printing services from Dinsmore and injection molding services from HARBEC. Dinsmore is a leader in the field of polymer 3D printing, providing high-quality parts with fast turnaround times. Our customers benefit from their expertise and their state-of-the-art equipment, which can print parts in a wide range of materials, including thermoplastics and elastomers. HARBEC, on the other hand, specializes in injection molding and can produce high-quality, custom-molded parts in a wide range of materials, including engineering thermoplastics, thermoplastic elastomers, and bioplastics.

In addition to polymer 3D printing and injection molding, our customers also have access to traditional manufacturing services from ADDMAN Precision Machining. With decades of experience in precision machining, ADDMAN has the expertise and equipment to produce high-quality parts for a wide range of applications. Whether you need complex machined parts, simple turned parts, or assemblies, ADDMAN has the capabilities to meet your needs.

3D Polymer Printing

Dinsmore drives prototyping and low-rate initial production activities within the ADDMAN portfolio. With extensive expertise in product go-to-market, we assist companies in developing

a tactical roadmap to establish a competitive advantage through additive manufacturing. Dinsmore has production capabilities that span SLA, DLS, FDM, MJF, and PolyJet modalities.

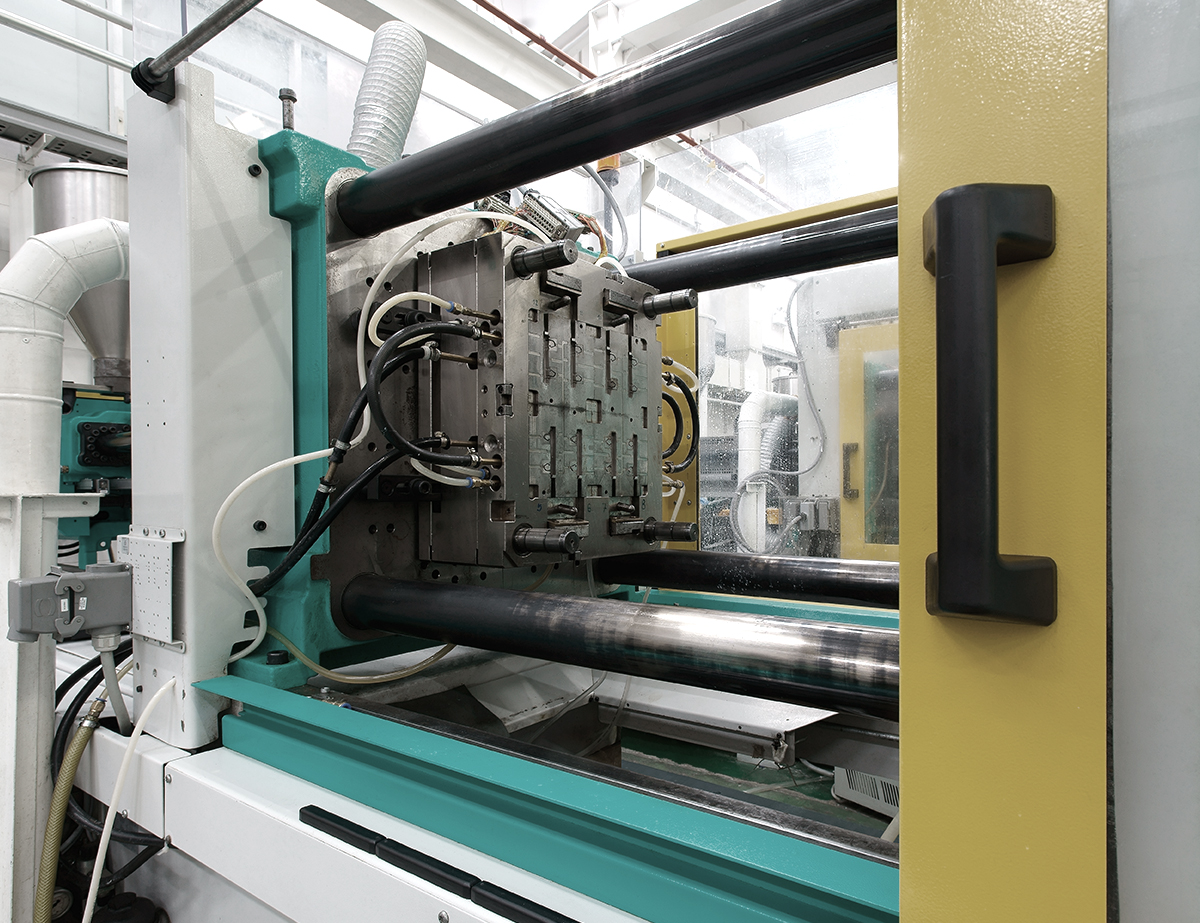

Injection Molding

In many industries, injection molding is crucial for fabricating various parts. Our domestic injection molding capabilities are fueled by the dedicated team at our HARBEC business. With more than 45 years of experience, we offer superior strength and product durability, fast production speeds, and the capacity to meet the need for high production volumes. All this is done in the name of sustainability with “The HARBEC Way” in mind. Meeting the needs of today without compromising the quality of the future.

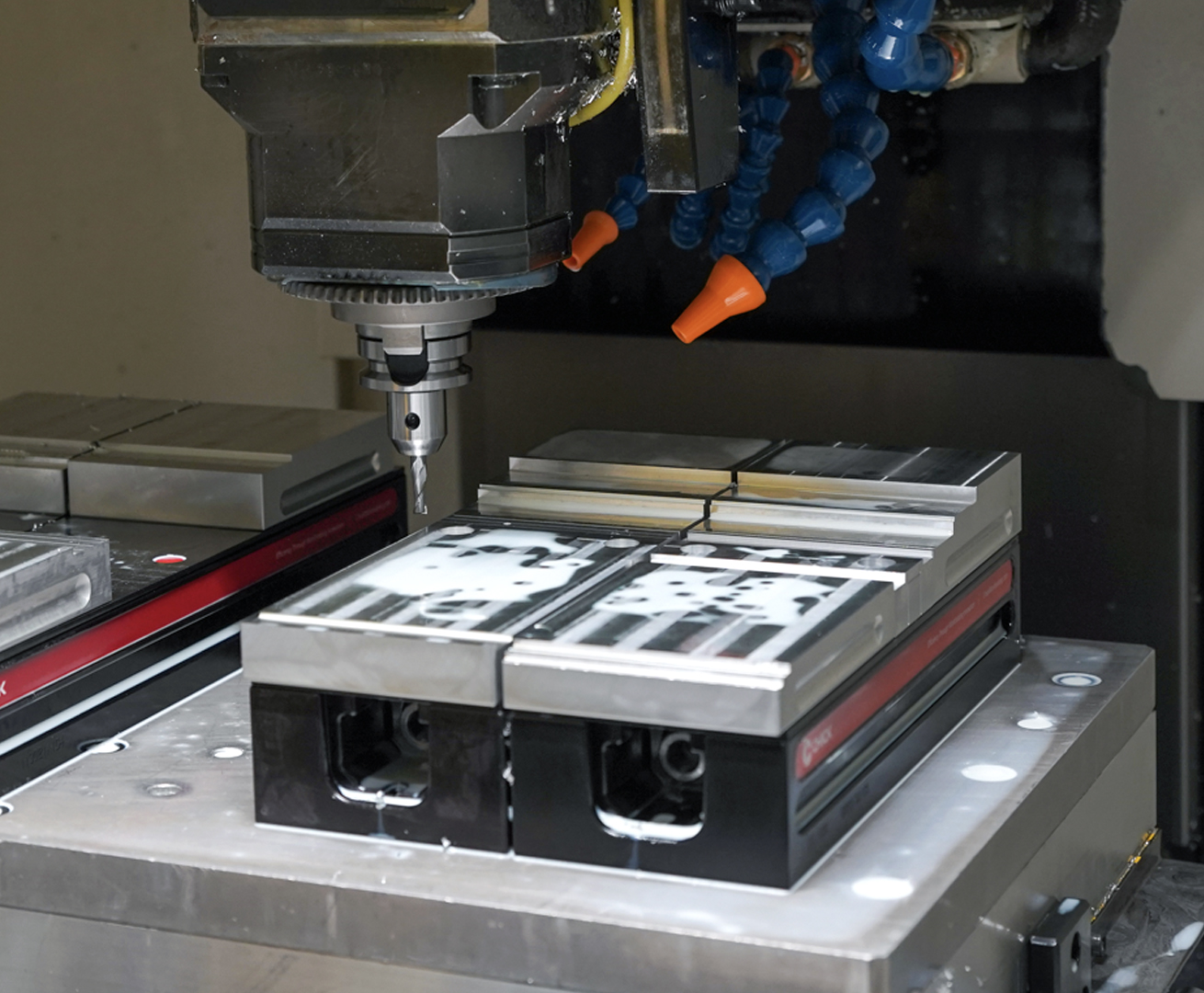

Traditional Manufacturing

A full complement of processing and finishing elements are available with ADDMAN’s Precision Machining footprint, which includes 5-axis CNC turning centers, wire EDM systems, and complete processing and finishing capabilities. With over 50 years of experience in Precision Machining, we have achieved the highest quality standards.

Certifications

Our Quality team has the experience, capabilities, equipment, and software to meet the demanding quality requirements of our diverse customer base. Through the ISO 9001 framework, we strive for excellence throughout the design, prototype, and product life cycle of a part. We are proud to deliver high-quality parts to our customers.

CERTIFICATIONS

- ITAR Compliant

- ISO 9001 / AS9100

- ISO 13485:2016

- ISO 14001:2004

- ISO 50001

- NIST 800-171 Compliance

- JCP: 0086270 / 0058842 / 0025691 / 0081082

- Exostar 3.55

- Class 8 Cleanroom

Together, we can speed up the innovation of tomorrow. Let's talk.

Our collective ability to create is boundless, limited only by the scope of our imagination. Your story is the starting point for this journey.