Castheon Inc is known for its rapid and robust AM process development that is optimized for optimal & isotropic microstructures, build capability, and high productivity AM Materials Development

Metallurgy & Print Parameter Development

Metallurgy & Material Development

At Castheon Inc, we are dedicated to advancing the capabilities of metal additive manufacturing (AM) through cutting-edge metallurgical and material development. Our team of experts works tirelessly to develop new metal alloys and optimize existing ones for use in AM applications. We are committed to achieving the highest levels of material quality, ensuring that our AM parts meet the most stringent industry standards for performance and durability. Our expertise in metallurgy and material development enables us to develop high-performance metal alloys that are ideally suited for use in aerospace, defense, medical, and other high-performance industries. With Castheon Inc, you can be confident that you are getting the best possible materials for your AM applications.

Print & Process Parameter Development

Castheon Inc is known for its expertise in developing and optimizing metal additive manufacturing (AM) processes. Our team of experts works closely with clients to develop AM processes that are optimized for optimal and isotropic microstructures, build capability, and high productivity. We have a deep understanding of the interplay between print parameters, material properties, and final part performance, which allows us to fine-tune AM processes to achieve the desired outcomes. Our expertise in process parameter development ensures that our clients can achieve maximum efficiency and cost-effectiveness in their AM operations.

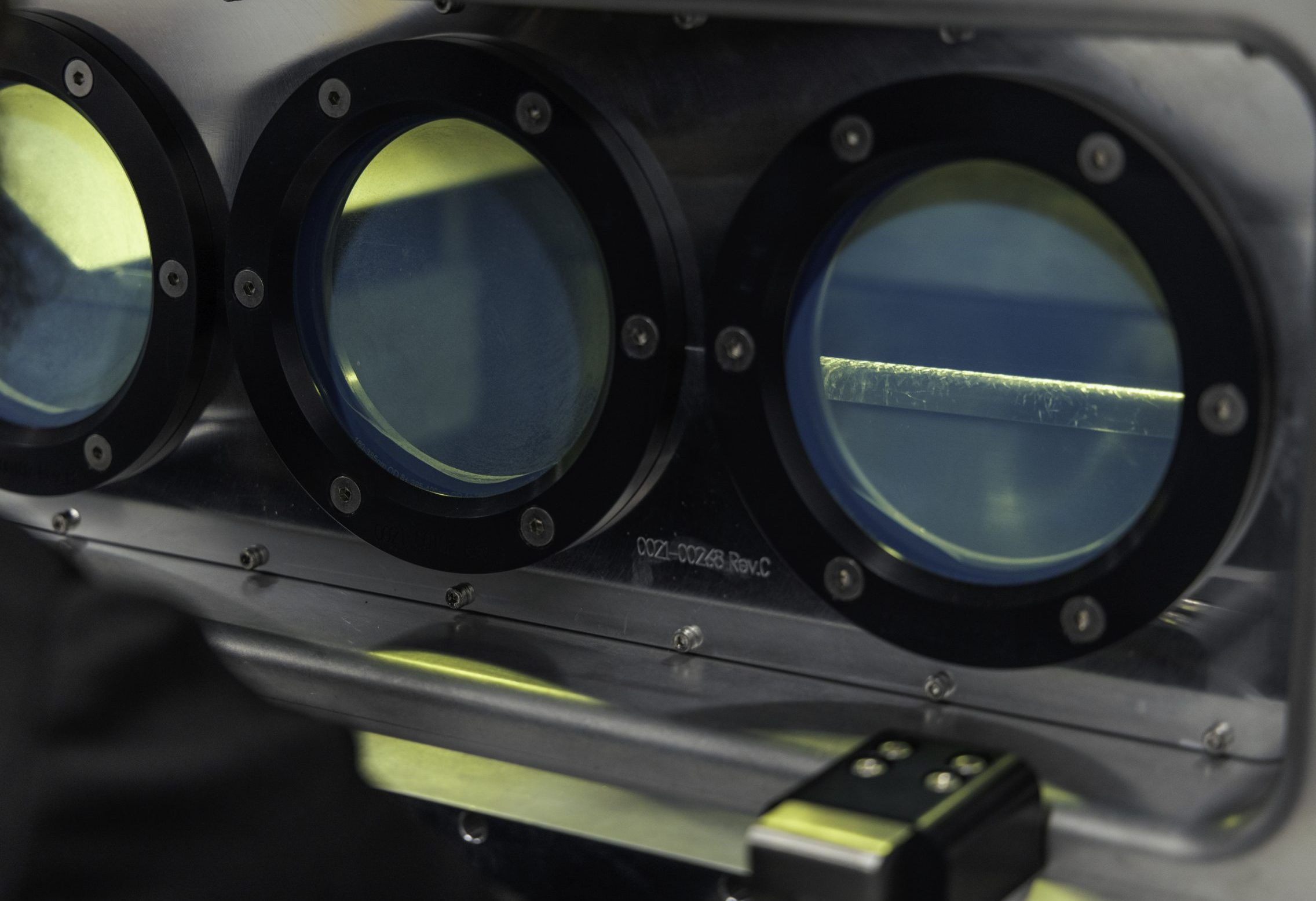

The Gao Block

The Gao block is a unique test part developed by Dr. Youping Gao, founder of Castheon Inc., to facilitate the development of new metal additive manufacturing processes and parameters. It is a complex geometric part that features a range of features, such as overhangs, undercuts, and fine details, which make it a challenging part to produce using traditional manufacturing methods. By using the Gao block, Dr. Gao and his team can test and optimize new metal additive processes and parameters, such as laser power, scanning speed, and layer thickness, to achieve the desired quality and consistency of parts. The Gao block has proven to be a valuable tool in the development of new metal additive processes and parameter optimization, enabling Castheon to offer its customers cutting-edge AM solutions that are optimized for optimal and isotropic microstructures, build capability, and high productivity.

Together, we can speed up the innovation of tomorrow. Let's talk.

Our collective ability to create is boundless, limited only by the scope of our imagination. Your story is the starting point for this journey.